Microsoft Announced Microsoft Dynamics 365 Copilot

In reality, Microsoft Dynamics 365 Copilot, an AI-driven assistant integrated into CRM and ERP systems, was unveiled in March 2023. Source

Natural disasters and geopolitical events, for example, might have an impact on supply chains. Copilot in Microsoft Supply Chain Center features a news model that collects all supplier-related news. With the help of Azure OpenAI Service, supply chain managers may alert suppliers with AI-generated and targeted emails. This is the first instance of generative AI systems being used directly in supply chain operations.

Source

Natural disasters and geopolitical events, for example, might have an impact on supply chains. Copilot in Microsoft Supply Chain Center features a news model that collects all supplier-related news. With the help of Azure OpenAI Service, supply chain managers may alert suppliers with AI-generated and targeted emails. This is the first instance of generative AI systems being used directly in supply chain operations.

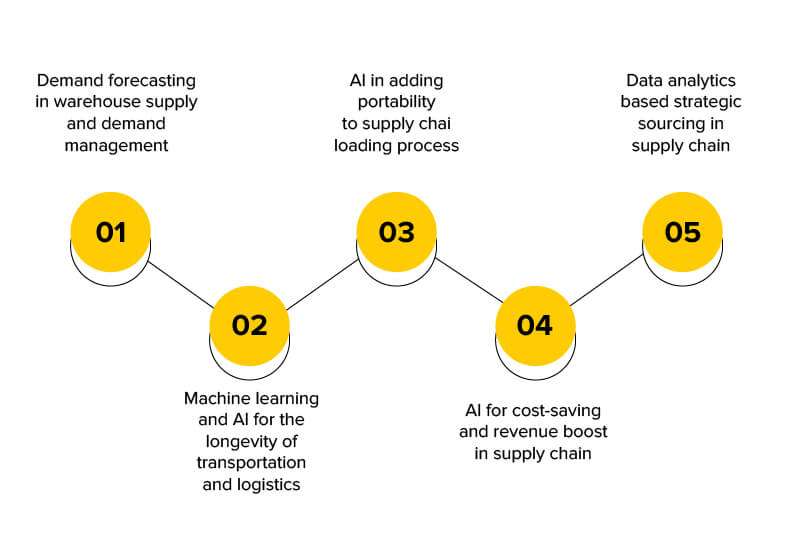

Main Benefits of Adding AI in Supply Chain Optimization

Source

The following benefits of artificial intelligence highlight the relevance of integrating AI in your business:

Source

The following benefits of artificial intelligence highlight the relevance of integrating AI in your business:

- Productivity gains: More than 60% of CEOs believe AI can automate decision-making and improve supply chain efficiency.

- The primary distinction between artificial intelligence techniques and the human brain is their ability to respond quickly to changes. AI software recognizes trends and attempts to identify potential areas for development.

- Only information analysis and machine learning can optimize warehouse operations and inventory. Product popularity is predicted and planned for by intelligent algorithms. As a result, the logistics department analyzes such information to select transportation and send it to the most in-demand locations.

- Reduced operational costs: Artificial intelligence technologies optimize every minute and mile of the delivery chain. So, according to United Parcel Service, an American logistics company, AI and quick route optimization saved the company $50 million.

Top 11 AI Use Cases for Supply Chain Optimization in 2023

The best 11 AI applications for supply chain management are highlighted in this article, along with tips for how supply chain managers might use them.A. Supply Chain Automation

1. Demand forecasting

When analyzing historical sales data, generative AI can take into account variables like seasonality, promotions, and economic situations. This data can be used to train the AI model to produce more precise demand estimates. This aids companies in improved resource allocation, inventory control, and market change detection.2. Back-office automation

Intelligent automation, or digital employees that mix conversational AI with RPA, can automate tasks like document processing.3. Automatic quality controls

Source

Computer vision (CV) systems with AI capabilities can assist in automating product quality inspections. These systems can increase production line productivity and accuracy because they don’t get tired. For instance, computer vision systems driven by AI can automate and enhance final product quality assurance.

Source

Computer vision (CV) systems with AI capabilities can assist in automating product quality inspections. These systems can increase production line productivity and accuracy because they don’t get tired. For instance, computer vision systems driven by AI can automate and enhance final product quality assurance.

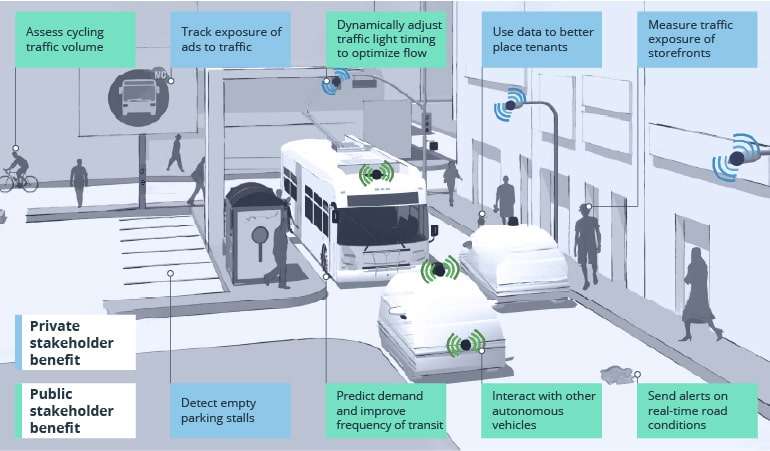

4. Automation of logistics

AI & automation can also be used to achieve effective supply chain logistics. Autonomous truck technology is being heavily invested in by businesses like Amazon, Tusimple, and Nuro.

5. Supplier risk assessment

Imagine you’re planning a big project, like building a cool model with different parts. Now, think of the companies that make those parts as your helpers. Sometimes, these helpers might face problems like being late or not doing a good job. Generative AI is like having a superhero sidekick that looks at a lot of information about these helpers – like how well they did before, their money reports, and even what people are saying about them in the news. This superhero helper can then tell you if your helpers are reliable or if there might be problems in the future. So, if the superhero sees there could be a problem, you can do things like finding new helpers or making backup plans to make sure your project goes smoothly. It’s like having a smart friend who helps you avoid problems before they happen!B- Automated Warehouse

Source

Source

6. Warehouse Robots

Another AI technology that has received significant investment to improve supply chain management for enterprises is warehouse robots. The market for warehouse robots, which was estimated to be worth USD 4.7 billion in 2021, is anticipated to expand at a CAGR of 14% from 2021 to 2026. As an illustration, the retail behemoth Amazon bought Kiva Systems in 2012 and renamed it Amazon Robotics in 2015. Currently, Amazon employs 200,000 robots in its warehouses. In 26 of Amazon’s 175 fulfillment centers, robots aid people in choosing, sorting, transporting, and storing things.7. Predictive Maintenance

C- Predictive Analytics/Forecasting

8. Bullwhip impact avoidance

The bullwhip effect is a common source of frustration in supply chain management. When tiny changes at one end of the supply chain are amplified as they move upstream/downstream, this phenomenon happens. By integrating data collected from customers, suppliers, manufacturers, and distributors, AI-powered forecasting solutions can assist in reducing demand and supply swings to regulate bullwhip. This can aid in the reduction of stockouts and backlogs.9. Inventory Optimization

AI-powered systems that analyze past demand and supply data and patterns can help determine the optimal inventory levels. This can reduce storage expenses and excess production.D- Improved Sustainability

Because the majority of an organization’s indirect emissions are produced through its supplier chain, sustainability is a growing concern for supply chain management. AI can assist in making supply chain activities more environmentally friendly and sustainable. To reduce the amount of kilometers driven, AI-powered technologies can help optimize transportation routes by considering factors such as traffic, road closures, and weather. DHL, for example, employs artificial intelligence to optimize vehicle routes and reduce fuel use, resulting in lower emissions and increased sustainability. Source

Source

11- Price Optimization

To produce effective price strategies, generative AI models can examine aspects such as customer demand, rival pricing, and market conditions. These tactics can assist organizations in increasing revenue, profit margins, and market share while remaining competitive.FAQ’s

- Automation of the back office Intelligent automation or digital employees that mix conversational AI with RPA can automate tasks like document processing.

- Automation of logistics AI and automation can also help with efficient logistics in a supply chain.

Supply chain and procurement leaders have been watching the launch of ChatGPT and other generative AI bots like Bard and Claude with bated breath. Indeed, generative AI may soon be extensively helping human decision-making across the company in areas such as sales, marketing, purchasing, and supply chain management.

RPA and other AI-powered tools can also help automate typical supplier communications such as invoice sharing and payment reminders. Automating these activities can assist in avoiding foolish hiccups created, for example, by forgetting to pay a vendor on time, which can have a detrimental impact on shipment and output.

Final Word

Due to their speed, effectiveness, and indefatigability, AI systems can help boost supply chain efficiency, minimize the demand for human labor, increase protection, and reduce expenses.

Supply chain management is impossible without the ability to predict capacity limits and consumer demand, and AI can be taught to do both effectively. Supply chains may become more resilient and sustainable with the help of artificial intelligence and big data.